Case Studies

SOUTH EDUCATION CENTER

Richfield, Minnesota

Founded in 1967, Intermediate District 287 was born out of a common goal to provide students with new options in vocational education. Over the course of 40 years, the district has added a reputable list of academic specialty areas and has grown into 13 west Minneapolis area districts. When the time came to create a learning space for special needs students, including programs for autism and an alternative learning center, the district went to every effort to ensure the building would be worry-free; as dynamic and innovative as the education. By enlisting the help of TSP engineering and design expertise, as well as applied HVAC solutions from Midwest Mechanical Solutions, ID 287 can proudly boast its new South Education Center as one of the most efficient and sustainable buildings in the entire state of Minnesota.

NOTED SUSTAINABLE FEATURES

- Geothermal system for heating and cooling

- Received all 10 points in EA credit-1 in LEED

- scoring system

- “Green” cleaning and maintenance program

- 64% more efficient than the energy benchmark

- Ultra-low 44kbtu per square foot

- Energy cost is $1.06 per square foot

- Rain gardens for stormwater control

- Roofing reflects sunlight for cooling efficiency

AWARDS

- LEED Certified

- ACEC Engineering Excellence Award

- SCEC Award

- Xcel Energy’s “Most efficient building designed

- and built for 2009”

Project Highlights

BUDGET:

25.5 Million

SIZE:

3 Stories, 108,000 square feet

DESIGN:

TSP

MECHANICAL CONTRACTOR:

Pearson Mechanical

MECHANICAL EQUIPMENT PROVIDER:

Midwest Mechanical Solutions

The QLCI provided a single product that is under the control of the mechanical contractor while delivering an effective displacement ventilation solution.

QLCI, DESIGNED BY TROX, DISPLACEMENT

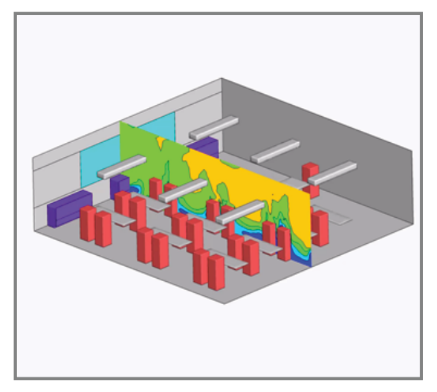

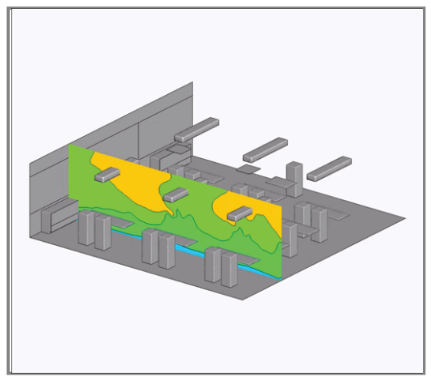

One of the most important pieces of equipment in the classrooms at South Education Center is the floor-mounted displacement induction ventilation units. These units utilize induction of ventilation outside air (OA) with a low-velocity air delivery method known as thermal displacement ventilation. This form of air delivery reduces the amount of OA required in the space by raising the ventilation effectiveness compared to a mixed air system. This decrease in required OA greatly reduces the cooling and heating energy required to serve the space. By using water in the zone/classroom to condition the air rather than taking the air back to a central station AHU, the amount of heating and cooling required is also greatly reduced. Displacement induction ventilation also provides fresh clean air in a directly occupied zone, by carrying the contaminants off-gassed from objects and people up to the unoccupied space. Once in the unoccupied space, the same contaminants are exhausted from the building.

QLCI displacement induction ventilation diffusers possess a combined cooling and heating coil to condition, and heat or cool the return air in that zone. This provides excellent, independent temperature control of each zone. The return air is pulled through the coil by the induction nozzles, mixed with the ventilation outside air, and supplied to the space down low at a very low velocity and slightly lower temperature than the space set point temperature. In addition, there are no moving parts or filters in the unit, which greatly reduces maintenance requirements. QLCI units provide the quietest air delivery method available. With no moving parts or fans placed in the classrooms, they can be designed quietly enough to meet ANSI S12.60 standards (35 dba). These units provide a space with fresh, clean air, and low CO2 levels, and replace typically noisy mechanical equipment with a quiet and low-maintenance alternative. Such benefits result in a healthier, distraction-free learning environment.

TROX MODEL DID-300 CHILLED BEAMS

Active chilled beams are used in the corridors, offices, administrative offices, and conference rooms of the South Education Center. Through induction, the chilled beam mixes ventilation (OA) air with the zone return air to deliver conditioned air through a 2-way linear diffuser. In this case, the air delivery method is at the ceiling and the zone is a mixed air zone. By using chilled water to condition the air directly at the zone rather than sending air back to a central station

AHU, the amount of fan energy and heating and cooling energy required are greatly reduced. The chilled beams have a heating and cooling coil which provides precise control of each zone. The chilled beams come in sizes from 3 feet to 14 feet long. By using active chilled beams In this facility the owner is able to save energy and provide precise control to individual zones.

When non-condensing chilled water is available, this device allows for treating small and variable occupant spaces effectively. Where displacement ventilation was not practical, the chilled beam was used because it allowed for a primary air system and non-condensing chilled water to deliver conditioned air. A more costly mixing system using a fan coil with traditional diffusers would have taken up more ceiling space and been more costly.

Haakon Custom Energy Recovery Unit

If you call the geothermal well-field and water-to-water heat pumps the “heart” of an HVAC system then surely you can call these Haakon energy recovery units the “lungs”. The South Education Center utilizes two 12,500 CFM units. The enthalpy wheels in these units recover both sensible and latent energy; they are 70% effective in recovering the energy from the return air stream and transferring it to the outside air stream. Built-in heating and cooling coils condition the air prior to delivering it to the space. These units are equipped with the latest safety devices and are designed for easy maintenance for the building facilities staff.

In addition, Haakon units have the industry’s lowest leakage rate of less than 1% at +/- 12” of static pressure. This low leakage rate saves the owner energy and reflects the excellent quality of construction. Finally, a single point power connection feeds variable frequency drives on the fans that ramp up and down based on duct static pressure. The use of VFD’s saves the school fan motor energy.

I have been involved in HVAC design for nearly 20 years. Rarely does a product standout due to the quality AND the level of service from the manufacturer. Haakon has provided exceptional engineering guidance and a response time second to none. The use of Haakon DOAS units with energy recovery wheels, water coils, correctly sized fans and uncompromising air path design helped us deliver primary air to the air delivery devices in a very effective and dynamic manner.

Trox Displacement Diffuser

Displacement Diffusers are used in the common areas, the gymnasium, and in various other specialty areas. Similar to the QLCI unit, these diffusers are a displacement system with a low air delivery method known as “displacement ventilation”. This form of air delivery reduces the amount of outside air required to the space by raising the ventilation effectiveness from 0.8 to 1.2. The resulting decrease in required ventilation (outside air) greatly reduces the cooling and heating energy required to serve the space. Air is mixed and conditioned at a fan coil or air handler and supplied to the displacement diffuser at low velocity. This provides a quiet and comfortable space.

Flow Control Pressure Independent Valve

All cooling and geothermal control valves at the South Education Center are pressure independent to provide precise control of the water GPM, regardless of pressure changes to the system. This accuracy increases the delta T on the system and saves cooling energy. The Flow Control pressure independent valve functions as a balancing valve, flow limiter, control valve, and flow meter all in one. The 100:1 turndown provides control at low flows where conventional control valves do not work. Flexibility in controls is an additional benefit, as pneumatic, electric proportional, 2-way or shut-off actuators can be used depending on what fits each project best. Flow Control’s industry-leading technology and experience is backed by the industry’s first and only delta T guarantee.

These [Delta P Values] have a complex integrated pressure independent feedback mechanism that is unbelievably accurate and reliable. A device with such ability contained in a single housing creates a very

easy installation and operation

Summary of All Equipment Provided at the South Education Center by MMS

- Addison Geothermal Water to

- Water Heat Pumps

- Armstrong Pumps

- Armstrong Air Seperators & Expansion Tanks

- Armstrong Plate Heat Exchangers

- Cesco Gravity Relief Ventilators

- Enviro-Tec Air Handler

- Enviro-Tec Fan Coil Units

- Fan Tech Dryer Booster Fan

- Haakon Energy Recovery Air Handlers

- Haakon Make-Up Air Unit

- Kees Pressure Relief Doors

- K-Flex Flex Connectors

- Trox QLCI Utility Cabinets & Duct Covers

- QLCI, designed by TROX, Displacement

- Ventilators

- and Diffusers

- Trox Chilled Beams

- Trox Flow Rate Controllers & Attenuators

- Twin City Fan Exhaust Fans

A BREATH OF FRESH AIR FOR A MINNESOTA SCHOOL DISTRICT

White Paper | QLCI Displacement Chilled Beams

Background

In 2002, the American National Standards Institute (ANSI) published ANSI S12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools. In essence, this standard calls for a 35 dBA (approximately NC27) acoustical level in all core learning areas.

The Anoka-Hennepin School District is the largest school district in Minnesota; it comprises most of the suburbs on the north side of Minneapolis. In 2004, the district allocated monies for the retrofit of existing elementary and middle schools based on IAQ improvement within the classroom. Interestingly, the addition of air conditioning for the schools did not qualify for the monies although the implementation of the space humidity control was allowed under the allocation. The Planning and Management Team for the school district was particularly attracted to the QLCI displacement with induction terminals as a solution for the planned classroom retrofits as well as continuing new school designs.

As the air conditioning of the classrooms did not qualify for the allocated funds, the heat transfer coils within the QLCI terminals were configured for heating only at this time. However, they were piped such that the inclusion of a chilled water circuit could be easily accomplished in the future. While there was no cooling contribution from the coil, the delivery of 55°F air from the air handling unit (required to accomplish dehumidification of the space) achieved a minimal level of classroom cooling.

QLCI Key Benefits:

- Improved removal of heat-associated contaminants inherent to thermal displacement ventilation systems.

- Classroom acoustical levels compliant with ANSI S12.60

- Designed for direct integration with a DOAS system to allow delivery of primary air at the space minimum ventilation rate.

- Lower maintenance requirements than other available classroom HVAC terminals.

In May 2005, the district installed a mock-up of the QLCI system in a classroom in an elementary school where the first retrofit was to be performed. Among the performance parameters studied were the acoustics and the CO2 concentration within the classroom. These were compared to those of an adjacent classroom served by a mixed air system (unit ventilators) under similar thermal loads and occupancy.

CLASSROOM ACOUSTICAL STUDIES

Subsequent to the issuance of this standard the Air Conditioning and Refrigeration Institute (ARI) commissioned ATS&R (a Minnesota-based A/E firm that specializes in educational facility design and renovation) and Kvernstoen, Ronnholm & Associates (a Minneapolis area acoustical

consultant) to perform a study of acoustical levels in area schools.

The primary objectives of the study were:

- Provide a survey of classroom acoustics in existing installations.

- Identify potential design solutions and estimated cost of achieving compliance in classrooms that did not meet the requirements of Standard S12.60.

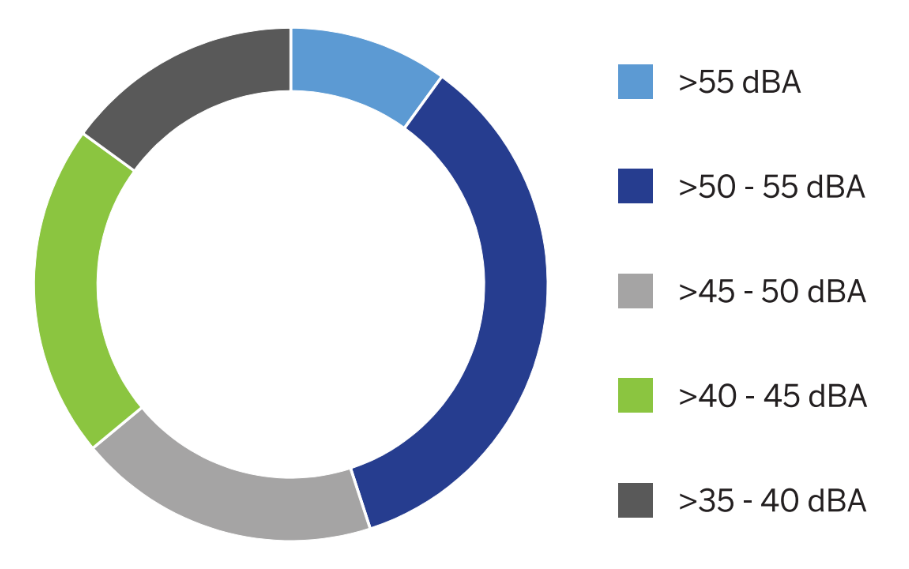

Sixteen schools (primarily located in Minnesota) and 48 classrooms were evaluated in the study, the results of which were published in October 2005. Ambient noise levels in the classrooms ranged from 36 to 58 dBA, resulting in only one (1) classroom complying with ANSI S12.60 requirements. The average classroom noise level was 47 dBA (approximately NC40). Figure 1 illustrates the summary of these acoustical tests.

ATS&R was contracted as the A/E consultant for the planned retrofit of the Anoka-Hennepin Schools. In June 2005, Kvernstoen, Ronnholm & Associates was commissioned to measure the combined acoustical performance of the three (3) QLCI displacement terminals installed in the mock-up at a combined primary air ow rate of 450 CFM (the minimum ventilation ow rate for the classroom). These tests were conducted during the late evening (approximately 10 PM) to minimize the effect of background noise. The results confirmed that the QLCI system produced noise levels compliant with Standard S12.60. A similar test of the unit ventilator in the adjacent classroom resulted in a noise level of 55 dBA.

CLASSROOM CONTAMINANT CONCENTRATIONS

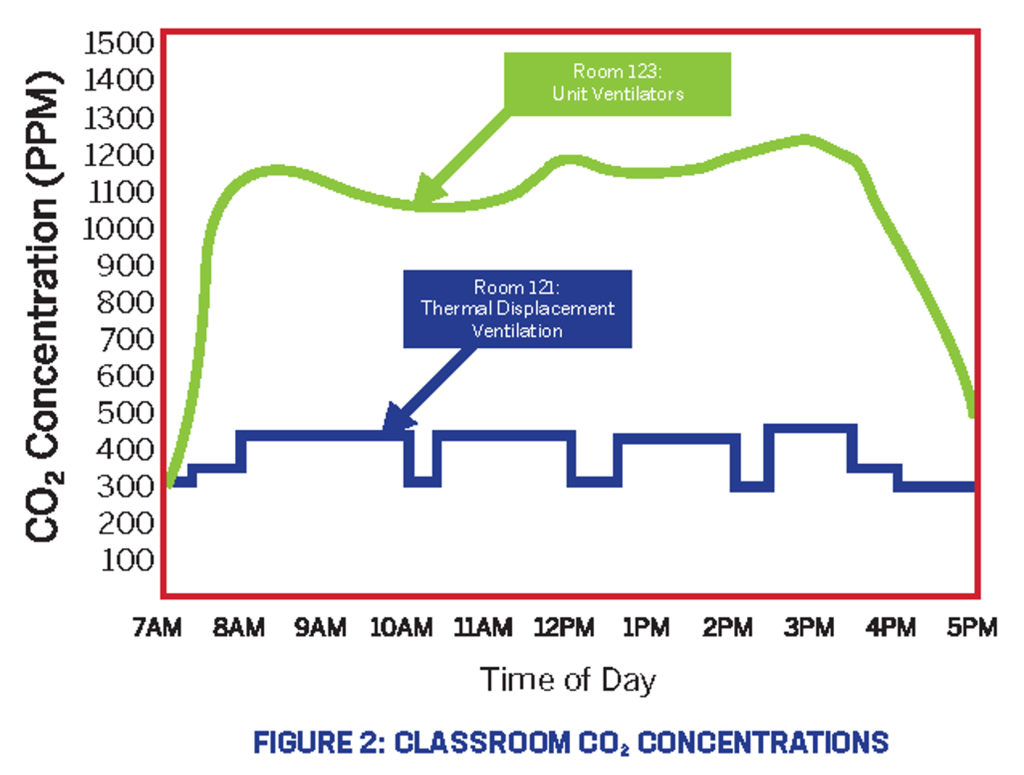

In an effort to substantiate the contaminant removal efficiency superiority of the QLCI displacement terminals (versus the unit ventilator), a CO2 sensor was hung at the center (6-foot height) of each of the aforementioned classrooms. Over a two-week period, CO2 levels were recorded in which the two classrooms were typically occupied. CO2 levels were considered the most important indicator as they are primarily the result of respiration and can logically be related to the airborne spread of disease. Figure 2 illustrates a typical daily plot of the CO2 concentrations in the two classrooms. Note that the levels in the classroom served by the unit ventilator increase rapidly as the classroom becomes occupied and then remain relatively constant throughout the day. There were slight peaks and valleys that results from periods when the classroom was unoccupied (recess, lunch, etc.), but these normally lagged the change in occupancy by half an hour or more. The overall average classroom CO2 level was approximately 1100 PPM.

In contrast, the average CO2 levels in the classroom served by the displacement (QLCI) system averaged 400 PPM, or 65% lower than those found in the original classroom. In addition, unoccupied periods were clearly evidenced by a sharp (and immediate) drop in CO2 levels. This should be expected as displacement systems remove airborne contaminants at the source, as opposed to simply diluting their concentration within the space. Therefore the odds of an occupant contracting a disease by airborne means were reduced by a similar 65% as well.

SUMMARY

Since the mock-up, the school district has retrofitted eleven schools with the QLCI system and has a number of other retrofits scheduled for 2007 and beyond. Citing the results of the District, several other districts in Minnesota have also used the QLCI system in both retrofit and new construction applications.

Purdue Substantiates QLCI Operation of Year-Round Displacement Ventilation

Questions continue to arise surrounding the correct value to apply for ventilation effectiveness, Ez, when determining code required minimum outside air per Table 6-4, ASHRAE 62.1-2019. In Table 6-4, ASHRAE outlined default values based upon distinct ventilation type and finite operational characteristics.

ASHRAE recognized the default values in Table 6-4 could not capture the myriad of ventilation and equipment designs, not to mention the enhanced control strategies, applied in industry practice.

Normative Appendix C defines the procedure for determining zone distribution effectiveness through the following measures: (1) CFD modeling coupled with supporting lab validated testing and (2) operational performance must be measured in BOTH cooling and heating modes.

In Table 6-4, for Stratified Air Distribution Systems, (Displacement Ventilation) the Ez default values were only defined for cooling mode operation. Now with the defined procedures per Normative Appendix C, the ability to establish Ez values for Displacement Ventilation during heating modes can now be applied.

Ventilation in HEATING mode.

Ventilation in COOLING mode.

Displacement Out Performs Mixed Air Ventilation for Contaminant Removal

Designers should investigate a method called vertical displacement ventilation or thermal displacement ventilation. This approach successfully uses natural convection forces to reduce fan energy and carefully lift air contaminants up and away from the breathing zone

Schools receive better IAQ, improved thermal comfort, improved acoustics for learning, and decreased maintenance with no moving parts.

Not All Displacement Ventilation is Created Equal

Go with a tested, validated and proven leader:

- Hundreds of school buildings with QLCI installed over decades

- Many school districts have installed QLCI equipment repeatedly based on delivered performance.

- Fully customizable equipment and accessories

- Only DIV manufacturers to have 3rd party independent data per Normative Appendix C

- Validated stratied displacement operation in BOTH cooling and heating

About Carson Solutions

Carson Solutions designs and manufactures HVAC equipment designed for occupied environments. We focus on innovative products that exceed industry standards to assist in providing the best environments in which we work and live. At Carson Solutions, we are devoted to improving the well-being of people and the occupied environments in which we work and live by producing innovative sustainable solutions that solve our customer’s needs and challenges.